Recycling PLA - a good step in circularity.

– Recycling PLA.

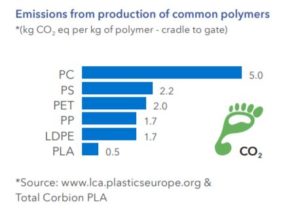

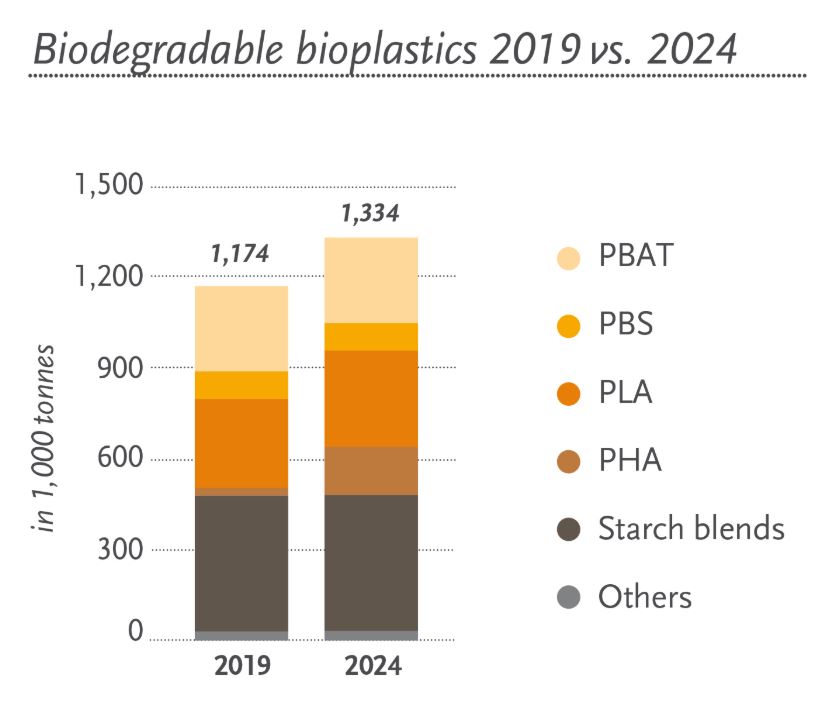

Bioplastics fit well in a circular economy, especially if they are recycled as much as possible at the end of their lifespan (CE Delft, 2017a). Some bioplastics, such as bio-PET and bio-PE, are already partially recycled. They are also sorted out from the plastic consumer waste for recycling. The bioplastic PLA (polylactic acid), which is the third bioplastic used by volume as packaging material, is not yet sorted out for recycling. This study explored whether this is possible and what the costs, benefits and environmental benefits would be. The exploration focuses on the bioplastic PLA in the plastic packaging waste of consumers in the Netherlands, now and in 2030.

The focus on PLA in this analysis does not mean that PLA is better or more sustainable than bio-PE or bio-PET or other bio-plastics. This focus has been chosen purely because PLA is the largest bioplastic on the packaging market that is not yet sorted out for recycling. This study did not compare different bioplastics, but looked at an increase in PLA and other bioplastics according to the current market distribution.

– PLA volume in the market now and in 2030.

We estimate that the share of PLA in plastic packaging waste from households is currently 0.1 to 0.4% based on statements from manufacturers and measurement of waste.

PLA producer Total Corbion estimates that PLA could take a market share of 10 to 20% by 2030 from packaging that is not a bottle or a flask. In the total consumer packaging market this would be 7 to 15%. The transition agenda for plastics, drawn up as part of the government-wide program for the circular economy, aims at 15% virgin bioplastics by 2030. Translated with the share of PLA now in the packaging market and taking into account uncertainties, this provides a picture of the future of 1 to 8, 5% PLA in the packaging market by 2030.

– Sorting PLA with NIR installations.

PLA can be sorted out with a NIR installation (Near InfraRed). Packaging is recognized optically on a belt and blown out of the waste stream after recognition. A test with German waste shows a sorting efficiency of 55%, but here use was made of packaging that is difficult to sort and sub-optimal system settings. NIR supplier TOMRA mentions a sorting efficiency for 3D PLA of 80-85%. These figures could be tested with Dutch waste by means of a sorting test with a source separator, an after-separator and a technology supplier.

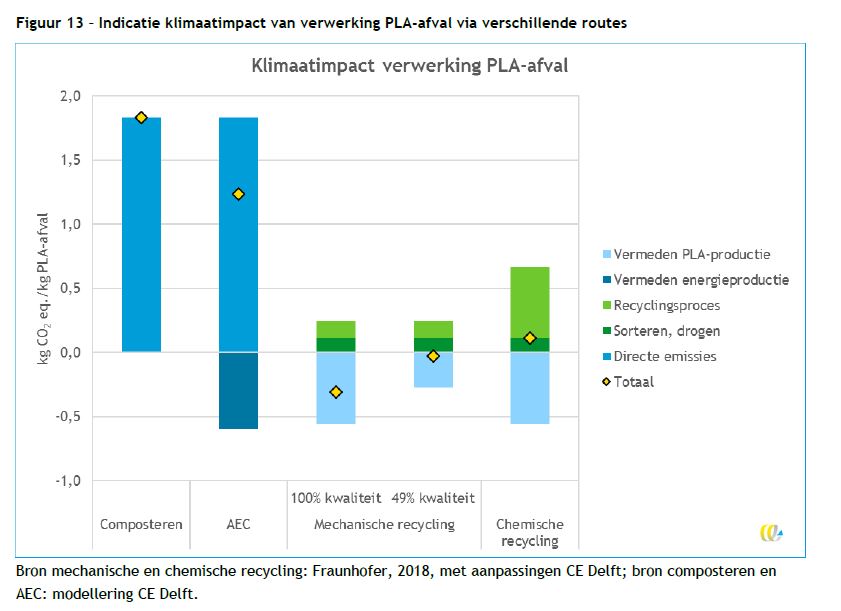

– Mechanical or chemical recycling of PLA and climate benefit.

The sorted PLA can be recycled both mechanically and chemically. Mechanical recycling of PLA is already applied to specific industrial waste streams that are quite clean. Chemical recycling is already being applied to production waste by Total Corbion in Thailand. Both routes lead to a reduction in the global climate impact

3 2.R82 – Exploration of sorting and recycling of bioplastic PLA – September 2019

of approx. 1.1 kg CO2-eq. per kg of PLA discarded, compared to incineration in waste power plants.

– Costs and benefits

In an analysis of the profitability of PLA sorting, the investment costs of a PLA sorting system and operational costs of PLA sorting have been estimated in dialogue with a number of current sorters. In addition, in dialogue with PLA producers, it was estimated how much sorted PLA material could yield if it is (chemically) converted back into new PLA. A distinction has been made between 3D PLA (containers) and 2D PLA (foil). Based on an average separation installation with a processing capacity of 50 ktonnes of plastic packaging waste, the net present value, payback time and the unprofitable top have been calculated for various percentages of PLA in the plastic packaging waste. This yielded the following results:

– With the current share of 0.1-0.4% PLA in the packaging mix, sorting out PLA is not economically profitable.

– Sorting out 3D PLA (trays and dishes) is economically more profitable than sorting out 2D PLA (foils).

– If the growth of PLA packaging were to concentrate on 3D-PLA, then, depending on the market price of lactic acid in particular, sorting would become profitable at 1 to 5% PLA in the packaging mix. The extra costs for sorting can then be paid from the proceeds from selling sorted PLA.

– With an optimistic share of 10% PLA in the packaging market, PLA recycling is economically attractive for sorters and recyclers because of the relatively high yields. The CO2-eq. Reduction of recycling of PLA is then approximately 16 kton / year compared to incineration in waste-to-energy plants (AECs).

This analysis must be explicitly seen as a first exploration, based on an average sorting situation. The situation may deviate positively or negatively at different sorters.

– Policy conclusions

In order to achieve 15% bioplastics by 2030, it is probably also (temporarily) necessary to stimulate bioplastics. In addition, it is worth considering, for example, at 2% PLA in the packaging market, also stimulating the sorting and recycling of PLA. In the packaging market, the existing Packaging Waste Fund offers good opportunities for this, because it manages an administration of all packaging on the Dutch market and also collects the producer responsibility contributions. For example, it is conceivable that the government will (temporarily) finance a lower rate for bioplastics. In addition, the rate for bioplastics that can be recycled would differ from those for which this does not apply. This is in line with the policy of the waste fund that applies a lower rate for easily recyclable packaging from 2019. In this way, the government could stimulate bioplastics in the packaging market with little implementation costs.

With regard to stimulating sorting of bioplastics at sorters, a (temporary) subsidy scheme for sorting companies for the purchase of additional sorting installations is obvious. A subsidy via the Waste Fund for this is also possible, but more indirectly. Then it would be a (temporary) premium on the sorting rate when PLA is sorted. On the other hand, there is a plea for an arrangement via the Waste Fund that some of the sorters are abroad and that subsidizing companies abroad raises questions.