PLA bottles and HPP:

Research rapport: Suitability Assessment of PLA Bottles for High-Pressure Processing of Apple Juice.

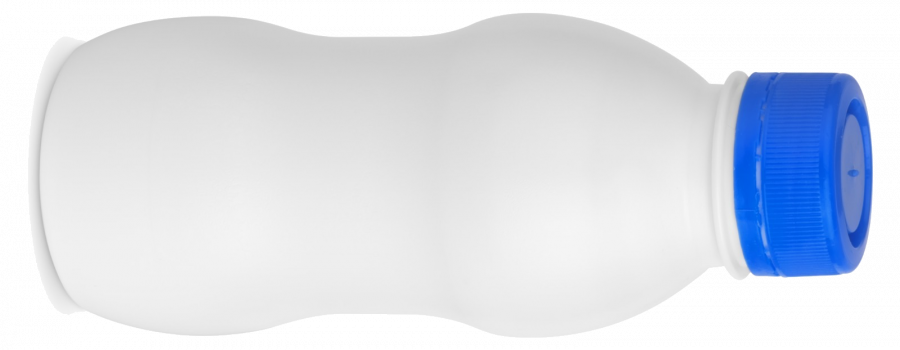

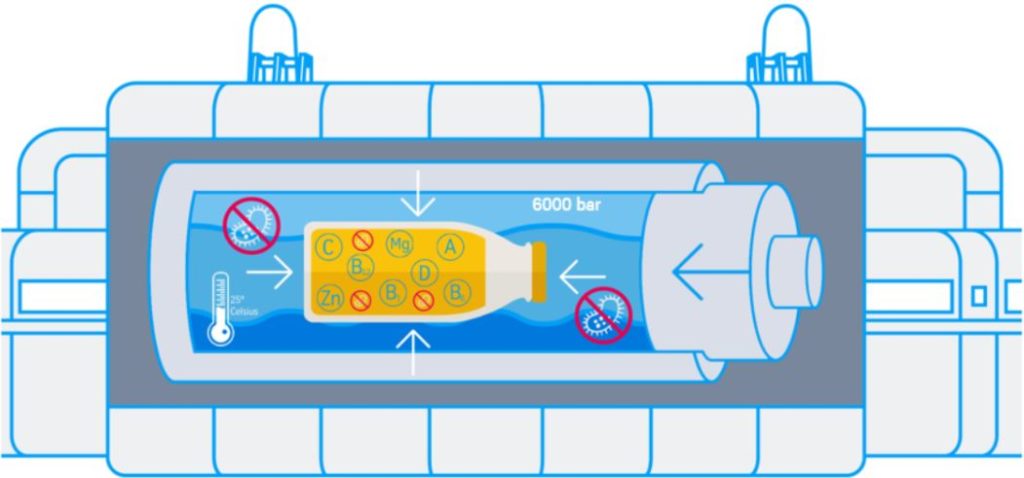

The aim of the present PET – PLA bottles HPP treatment study is to assess the use of plant-based (PLA) bottles as an alternative to PET ones for high-pressure processing (HPP) of apple juice. The treatment of Poly lactic-acid bottles at 600 MPa for 3 min did not cause alterations in the packaging shape and content, confirming the suitability of PLA bottles to withstand HPP conditions as well as PET bottles. Quantification of mesophilic bacterial and fungal load suggested HPP treatment can be effectively applied as an alternative to pasteurization for apple juice, and other fruit and vegetable juices, packed in PLA bottles since it guarantees microbial stability during at least 28 days of refrigerated storage.

The headspace gas level did not change significantly during the 28 days of refrigerated storage, irrespective of the bottle material. Color parameters (L*, a*, and b*) of the HPP-treated juice were similar to those of the fresh juice. Irrespective of the packaging type, the total color variation significantly changed during storage, showing an exponential increase in the first 14 days, followed by a steady-state until the end of observations. Overall, PLA bottles proved to offer comparable performances to PET both in terms of mechanical resistance and quality maintenance.

PLA bottles HPP treatment, the result:

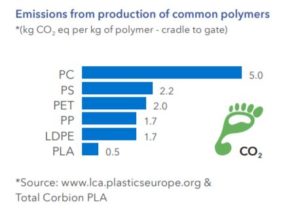

Today, consumer choices are driven by quality-related factors and by environmental sustainability aspects, which are especially related to the packaging system. The reduction of environmental impacts arising from the packaging is an effective strategy for the overall sustainability improvement, especially for products characterized by a high packaging relative environmental impact, such as juices and beverages. In this context, premium fruit juices processed with non-thermal technologies are available, but the possibility to couple a green processing technology with a green packaging system has not been exploited yet. The present study assessed the feasibility of employing PLA bottles as an alternative to PET bottles, for the packaging and subsequent HPP treatment of apple juice.

In a perspective of making the food chain sustainable, PLA and other bioplastics may replace conventional plastics for fresh and minimally processed products, offering sufficient performances able to maintain the shelf-life standards. This study proved that PLA is a valid sustainable alternative to conventional PET bottles for the packaging and HPP treatment of apple juice due to its:

1-Biobased nature,

2- compostability/recyclability,

3- mechanical resistance and ability to restore the initial shape after HPP treatment,

4- protection offered to the product, which is comparable with PET for short-term storage.

The rapport also proved the effectiveness of HPP for the stabilization of juices and demonstrated the potential of non-destructive gas measurement systems for the verification of diffusional properties of bottles.